In today’s fast-paced industrial world, efficiency is no longer just an advantage—it’s a necessity. And nowhere is this more evident than in the rise of advanced belt conveyor systems. Among the latest innovations, SMART Sync stands out as a game-changer. This motorized flat belt conveyor is more than just a way to move products—it’s an intelligent system designed to optimize automation, reduce downtime, and bring unprecedented precision to material handling across industries.

The Rise of Smart Conveying: Why Automation Needs an Upgrade

As industries scale and customer demands evolve, traditional mechanical systems often fail to keep up. SMART Sync was developed to bridge that gap, integrating the reliability of a motorized belt conveyor with the intelligence of smart automation systems.

While conventional conveyors rely heavily on manual oversight and fixed-speed operations, SMART Sync incorporates smart sensors, programmable logic controllers (PLCs), and dynamic speed control. This means smoother transitions, consistent product spacing, and minimized human intervention—critical features in modern production lines.

What Makes SMART Sync “SMART”?

Intelligent Motorization and Speed Adaptability

Unlike older conveyor systems that run at constant speeds, SMART Sync adjusts dynamically based on workflow requirements. The motorized system uses real-time data from sensors to optimize speed, reduce bottlenecks, and maintain flow uniformity. This adaptability leads to fewer system jams and significantly less product damage.

Precision Control for Delicate Applications

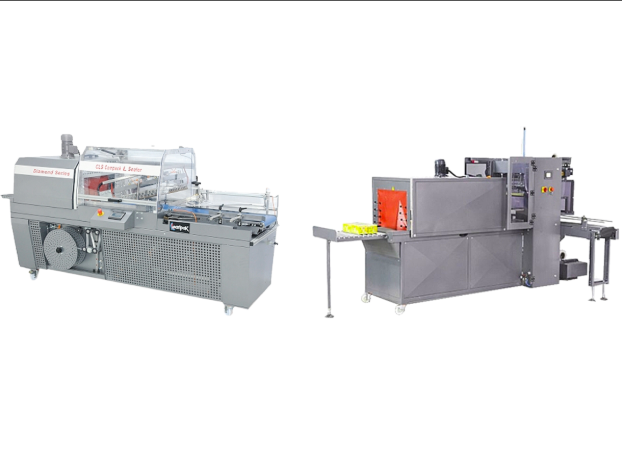

SMART Sync shines in precision-focused applications like packaging, pharmaceuticals, and electronics, where timing and spacing are everything. In automated packaging lines, such as those using a POF shrink film machine, precise alignment and timing ensure optimal wrapping without wastage or misalignment.

By syncing motion with downstream machines, SMART Sync helps maintain perfect synchronization, boosting both performance and product integrity.

Built for Today, Scalable for Tomorrow

Modular Design

SMART Sync is built with modularity in mind. Users can expand, reroute, or scale systems with minimal effort. This flexibility makes it an ideal solution for businesses planning growth or adapting to seasonal production changes.

Energy Efficiency

Beyond its brains and brawn, SMART Sync is also an energy-conscious solution. The motorized belt drive is designed to reduce energy consumption without sacrificing performance, an important factor for sustainability-conscious manufacturers.

Seamless Integration with Existing Automation

One of SMART Sync’s most impressive features is its plug-and-play compatibility with existing smart factory setups. Whether it’s part of a robotic assembly station or linked with a machine shrink wrap unit, SMART Sync adapts to upstream and downstream systems via standard industrial communication protocols like EtherNet/IP or Modbus.

This means companies don’t need to overhaul their entire system to enjoy the benefits. SMART Sync fits right in, bringing smart motion control and modular design to complex production environments.

Real-World Impact: Where SMART Sync Excels

- Pharmaceuticals: In sterile environments, SMART Sync ensures contamination-free movement with low-noise, smooth belt operation.

- Electronics: Precision-driven assembly lines benefit from SMART Sync’s consistent product positioning and anti-static materials.

- Food & Beverage: Wash-down designs and hygienic materials make SMART Sync perfect for environments with strict safety standards.

- Packaging: SMART Sync seamlessly integrates with packaging machinery, ensuring perfect timing for sealing, labeling, or wrapping operations.

Conclusion

In a world where speed, precision, and intelligence define industrial success, the SMART Sync motorized flat belt conveyor leads the charge. By fusing traditional material handling with smart automation, it offers a transformative leap forward in how factories and warehouses operate.

Whether you’re running a high-speed packaging line or upgrading a legacy system, SMART Sync offers a future-proof solution that delivers real-time adaptability, system integration, and energy-efficient performance. As industries push toward Industry 4.0, the demand for smarter, more intuitive conveying systems will only grow—and SMART Sync is ready to meet that future head-on.

Most Commented Posts