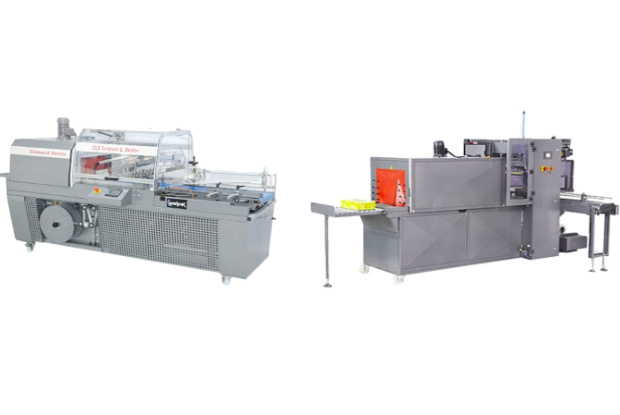

In packaging and manufacturing industries, shrink machines play a crucial role in protecting products, improving presentation, and ensuring efficiency. Two of the most widely used types are the polyolefin shrink machine and the polyethylene shrink machine. While both serve similar purposes, understanding their differences is vital for selecting the right equipment for your operations.

Understanding Shrink Machines

Shrink machines are designed to wrap products with heat-shrinkable films. When exposed to heat, these films contract tightly around the item, providing secure packaging. Shrink packaging enhances product stability during transportation, improves shelf appeal, and can even extend the shelf life of food products by providing a protective barrier.

Polyolefin and polyethylene are the most commonly used shrink films, and their respective machines are optimized to work with these materials. The choice between the two depends on the desired finish, product type, and operational requirements.

Polyolefin Shrink Machine Overview

A polyolefin shrink machine uses polyolefin film, which is known for its clarity, strength, and resistance to punctures and tears. Polyolefin films are food-safe, making them ideal for packaging consumables such as baked goods, fresh produce, and frozen foods.

Key advantages of polyolefin shrink machines include:

- High Clarity: Products are showcased clearly, enhancing visual appeal.

- Strong Seal: The films create tight, durable seals that reduce the risk of product damage.

- Resistance to Temperature Fluctuations: Polyolefin films maintain integrity under varying storage and transport conditions.

- Eco-Friendliness: Polyolefin films are recyclable, making them a sustainable choice for businesses looking to reduce environmental impact.

These machines often feature adjustable temperature settings, conveyor speed control, and easy-to-use sealing mechanisms to accommodate different product sizes and packaging needs.

Polyethylene Shrink Machines Overview

Polyethylene shrink machines, on the other hand, are designed to work with polyethylene films. These films are generally more flexible and cost-effective but may offer less clarity and puncture resistance compared to polyolefin films. Polyethylene shrink packaging is commonly used for bulk items, industrial products, and packaging where visual clarity is less critical.

Advantages of polyethylene shrink machines include:

- Affordability: Lower cost of film and machine makes it suitable for budget-conscious operations.

- Flexibility: Polyethylene films are highly adaptable for irregularly shaped products.

- Heat Efficiency: Requires lower heat for shrinking, which can be energy-efficient for large-scale packaging lines.

While polyethylene shrink machines are effective for protecting products, the resulting packaging may not provide the premium look that polyolefin shrink machines offer.

Key Differences Between the Machines

Understanding the differences between polyolefin and polyethylene shrink machines can guide the choice of equipment:

| Feature | Polyolefin Shrink Machine | Polyethylene Shrink Machine |

| Film Clarity | High | Moderate |

| Strength | Strong, puncture-resistant | Moderate, more prone to tearing |

| Food Safety | Suitable for food products | Less commonly used for direct food contact |

| Temperature Tolerance | High | Lower |

| Cost | Higher | Lower |

| Environmental Impact | Recyclable | Less eco-friendly |

These differences highlight that polyolefin shrink machines are typically chosen for premium, high-visibility products, while polyethylene shrink machines are ideal for bulk, industrial, or cost-sensitive applications.

Applications and Industry Uses

Polyolefin shrink machines are widely used in food packaging, retail product wrapping, and cosmetics, where appearance and product integrity are crucial. Polyethylene shrink machines, due to their affordability and flexibility, are often used for warehouse packaging, multipacks, and large-scale shipping.

Choosing the right machine depends on the balance between product presentation, protection, operational efficiency, and budget constraints. Many businesses may even use both types for different product lines to optimize performance and cost.

Conclusion

Selecting between a polyolefin shrink machine and a polyethylene shrink machine requires careful consideration of product type, packaging goals, and operational priorities. Polyolefin machines offer high clarity, durability, and food-safe features, making them ideal for premium packaging. Polyethylene machines provide flexibility and cost efficiency for bulk or industrial items. Understanding these differences ensures businesses invest in equipment that meets their specific needs. For comprehensive packaging solutions, pairing the right shrink machine with a reliable sealer machine can further enhance productivity and product presentation.

Most Commented Posts